AREAS FOR USE

The standard Shot-Lock range is designed for indoor applications. Regular galvanised systems should not be used in areas that have levels of corrosion or elevated levels of heat or moisture.

For installations that are within corrosive areas consult with Zip-Clip Technical Department.

INSTALLATION

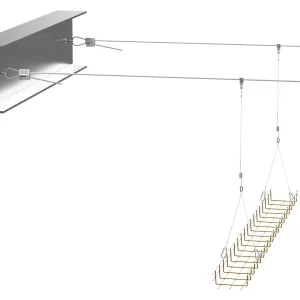

• The first step of the installation process is to fasten the shot-fire bracket to the base material.

• The second step of the process is to install the Zip-Clip locking device and connect to the intended application.

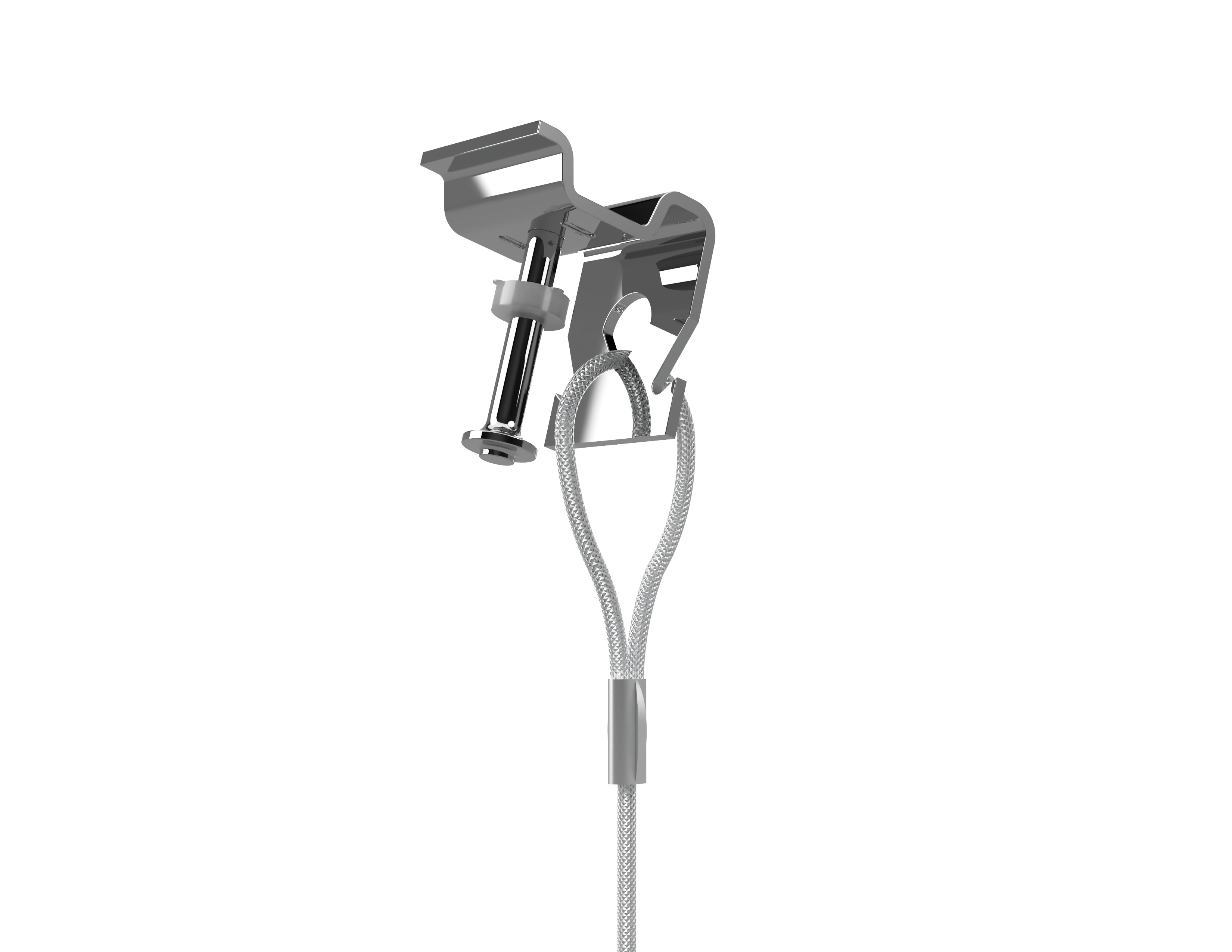

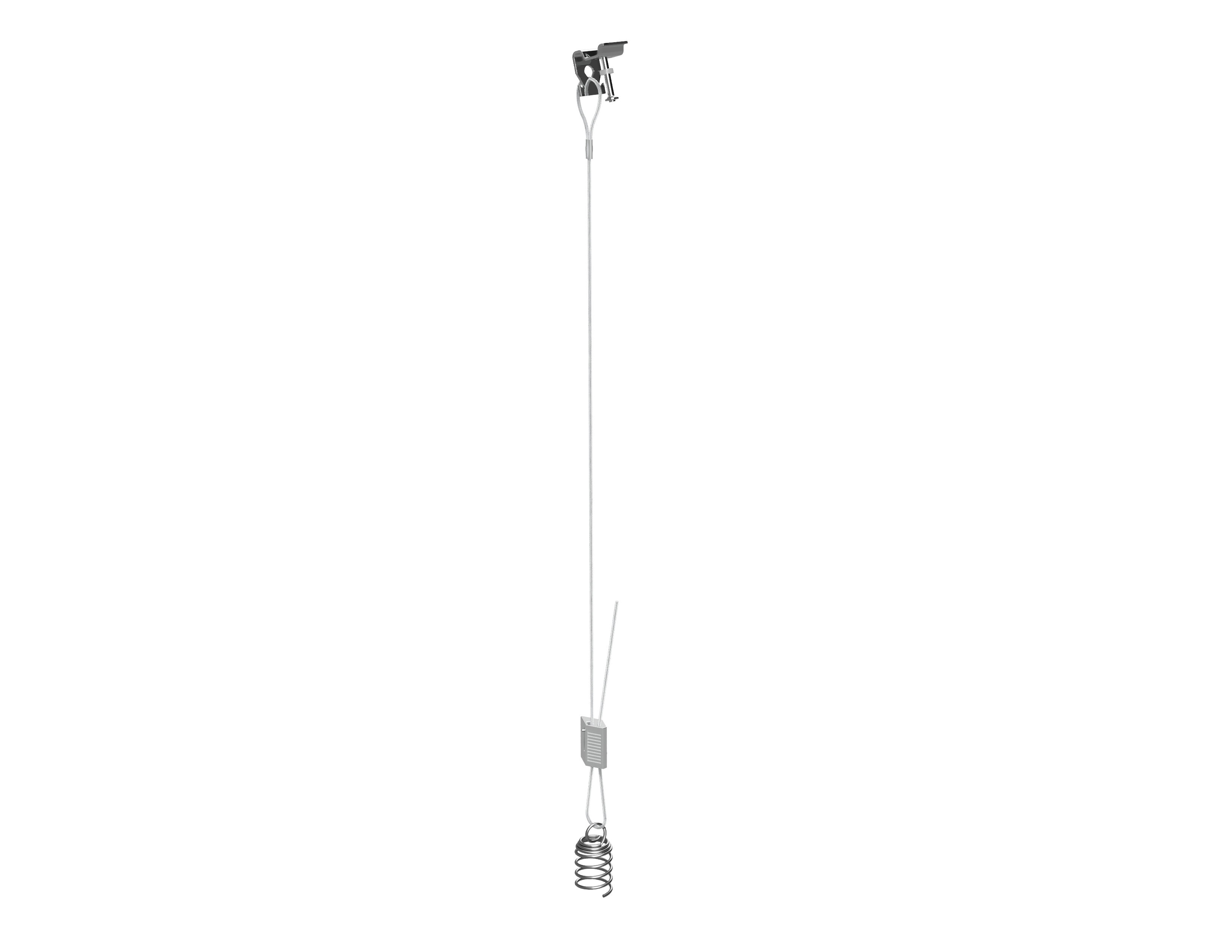

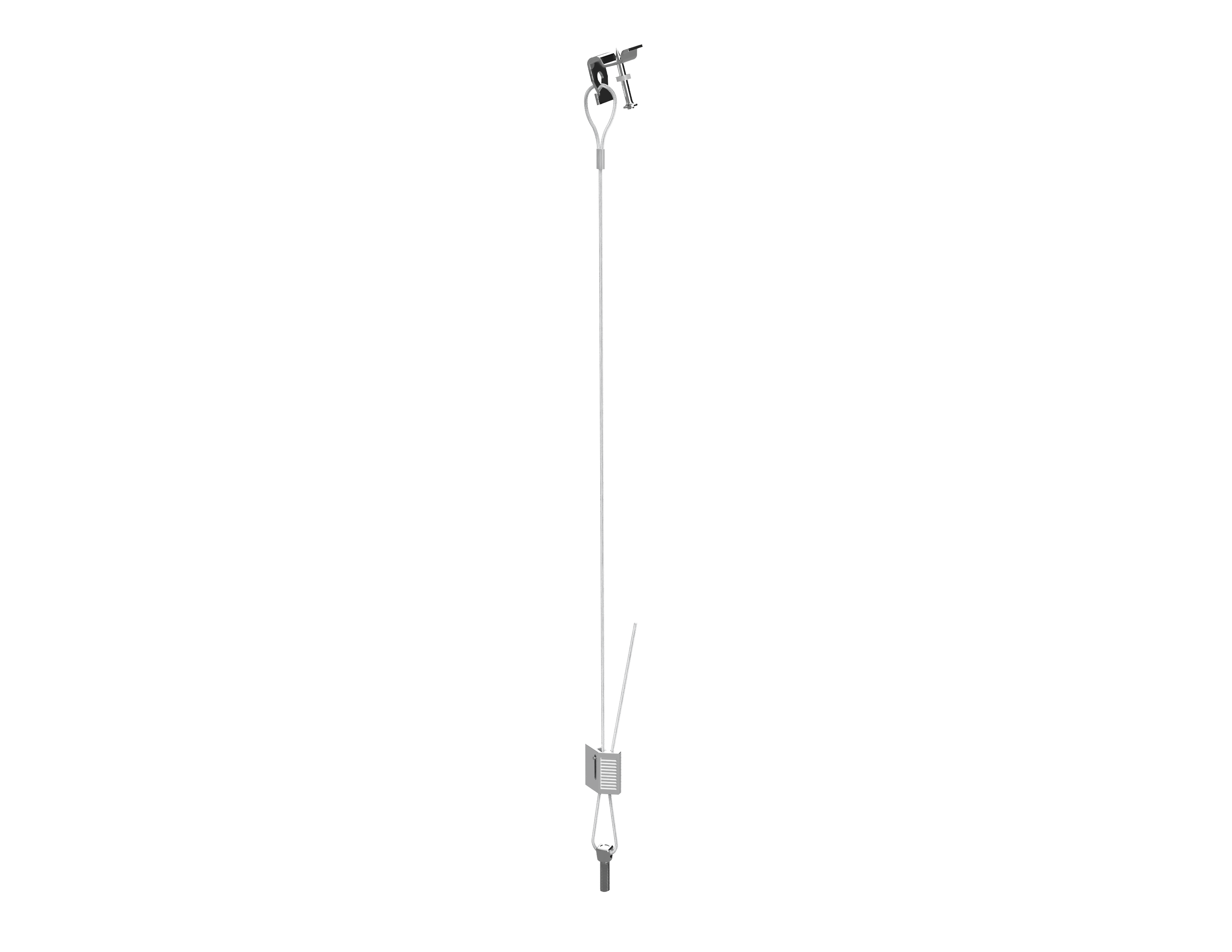

STEP 1:

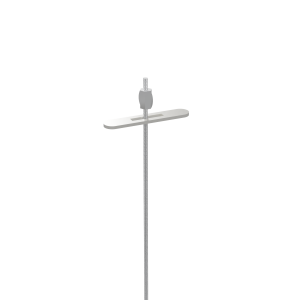

Attaching the shot-fire bracket to the base material

Tools required: PAT cartridge nailing tool.

Before installation Zip-Clip recommends referring to Construction Fixings Association guidance notes on the use of powder-actuated fixing systems.

Always perform test fixes before commencing installations to ensure fixing is suitable for base material.

- Ensure the substrate is suitable for nail and cartridge.

- Locate nail into barrel of the Powder Actuated Tool.

- Follow the gun manufacturers’ firing guidelines and CFA guidance notes.

- Confirm quality of fix before loading.

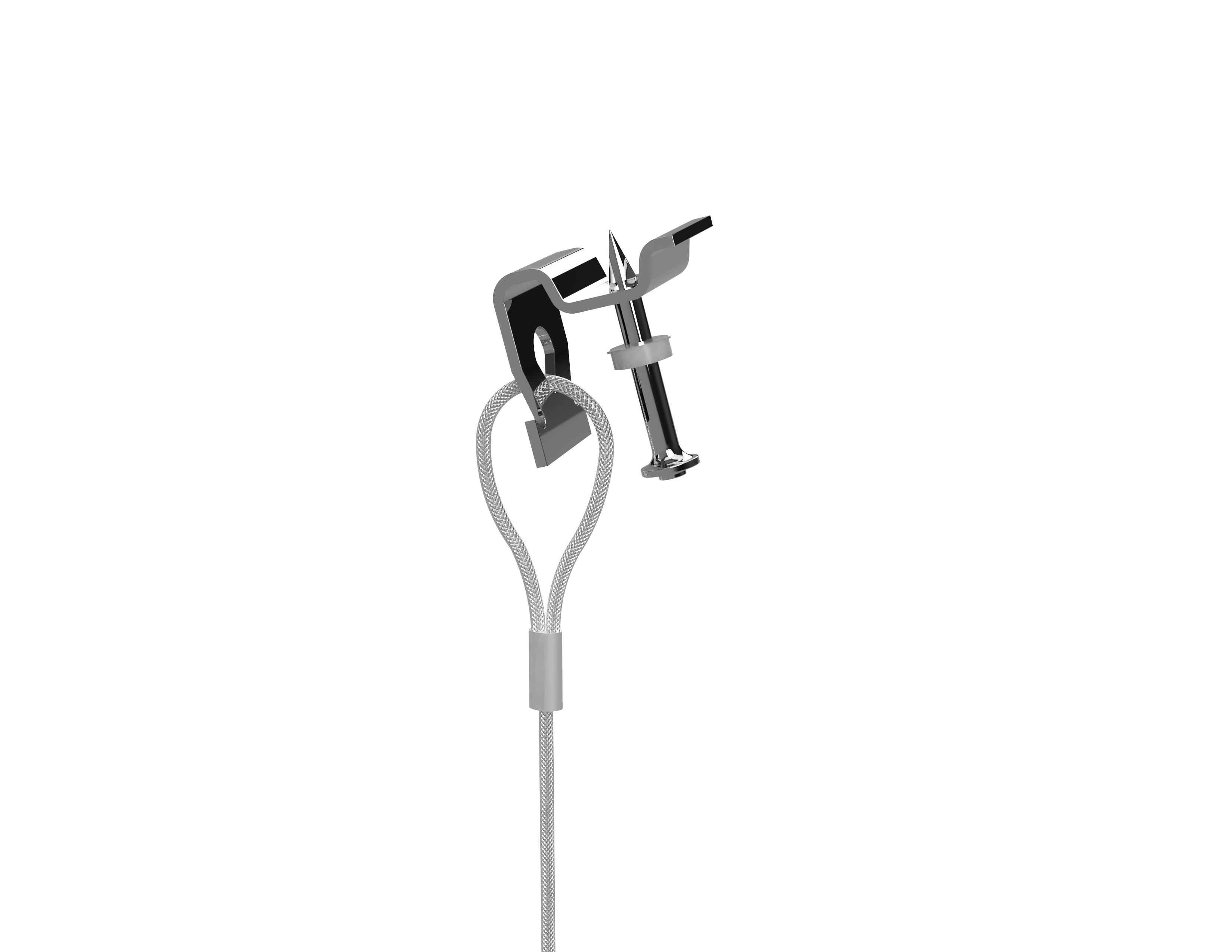

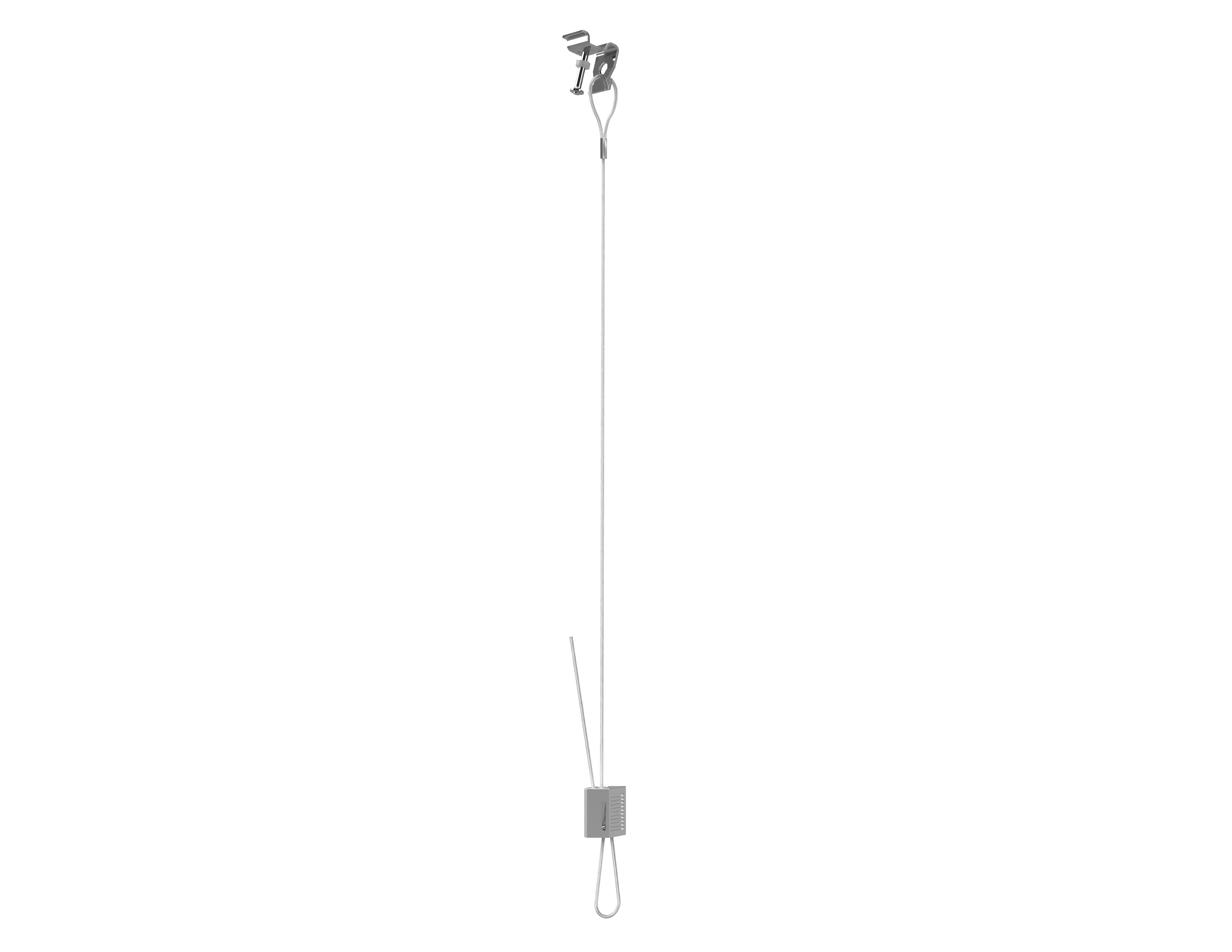

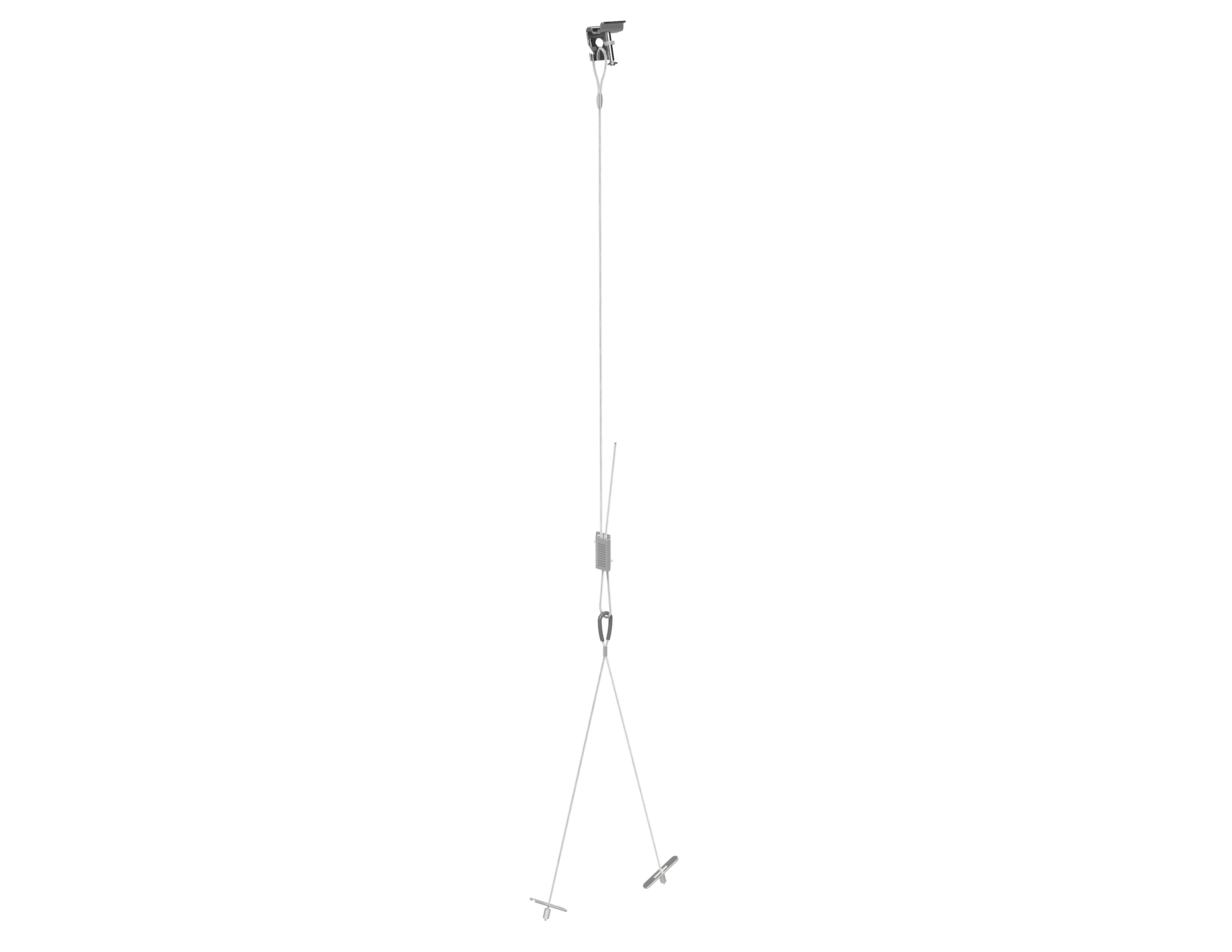

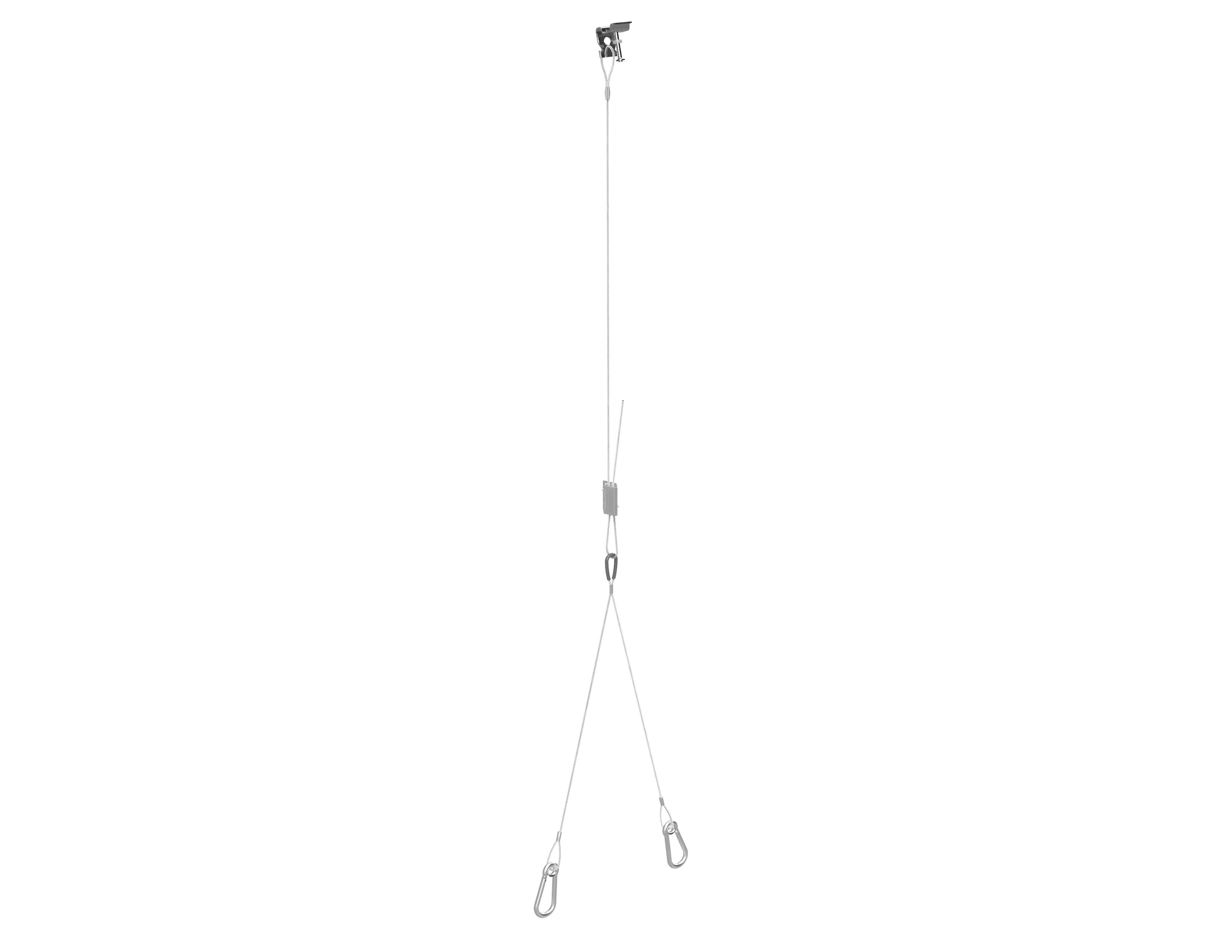

STEP 2:

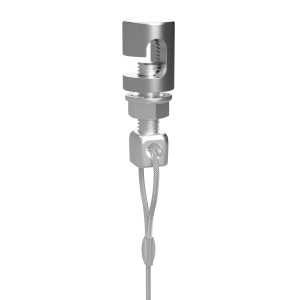

Installing the Zip-Clip locking device

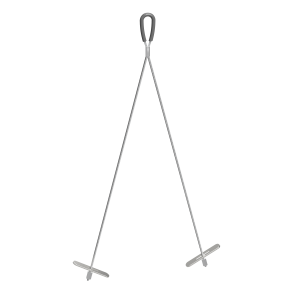

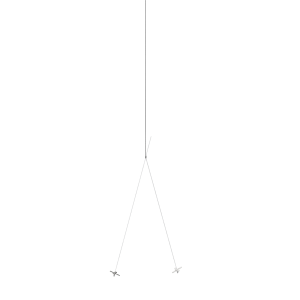

Once the 90° bracket has been installed, a Zip-Clip locking device can be used to attach the wire to the service.

- Pass the wire rope through the Zip-Clip device in the direction of the arrow.

- Pass wire rope through or around your required fixture/application and back through the Zip-Clip leaving 15 cm of wire protruding.

- Confirm engagement of the Zip-Clip on the wire by pushing the pinin the opposite direction to the arrows indicated.